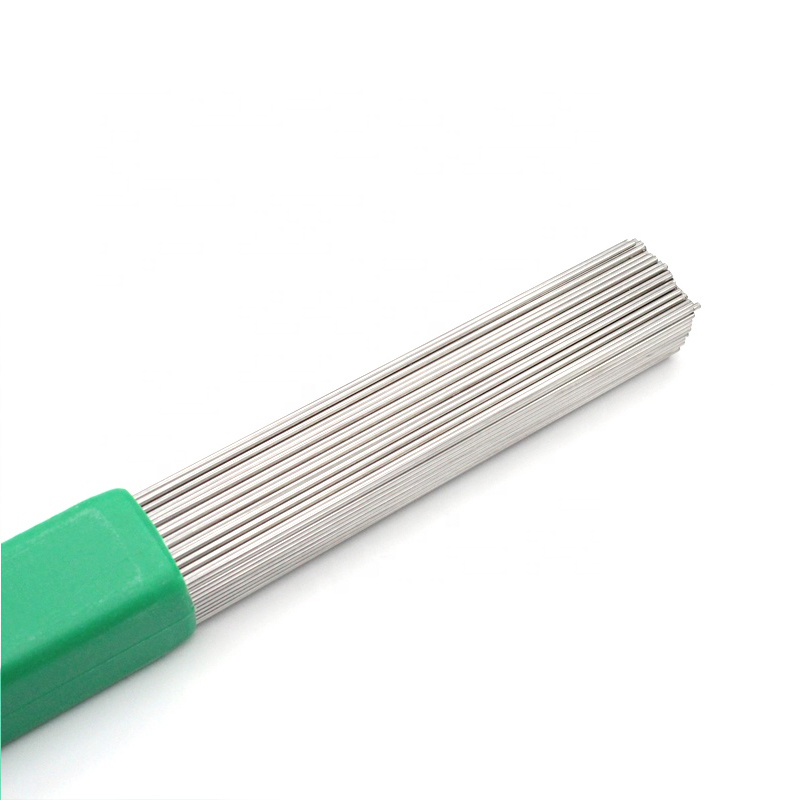

ER1100 A5.10, ALUMINIUM SY ALUMINIUM ALLOY Electrodes sy rods

ER1100 dia tena mahatohitra ny fanafihana simika sy ny toetrandro.Izy io dia firaka malefaka izay tena azo endrika ary ampiasaina betsaka amin'ny vokatra manify sy foil.Izy io dia manana toetra mando tsara ary ampiasaina ho toy ny firaka filler ho an'ny tanjona welding.Ny toetra irina amin'ny firaka dia ny famaranana mamirapiratra azo amin'ny anodizing.

Fampiharana mahazatra: fifanakalozana hafanana;fitaovana fikarakarana sakafo;rivets;tariby mamatotra;metalizing

| Kilasy AWS: ER1100 | Fanamarinana: AWS A5.10/ A5.10M:1999 |

| Ampahany : ER1100 | AWS/ASME SFA A5.10 |

| Welding toerana: F, V, OH, H | ankehitriny: DCEP-GMAW AC-GTAW |

Toetra mahazatra (toy ny welded)

| Conductivity: | 59% IACS (-12) |

| Henjana, kpsi: | 13 |

| loko: | grey |

| Teboka fandoroana | 1215⁰F | Solidification | 1090⁰F | hakitroky | 0,098 lbs/cu In. |

Chemistry Wire mahazatra araka ny AWS A5.10 (ny sanda tokana no ambony indrindra)

| Si + Fe | Cu | Mn | Zn | Hafa | Al | ||||||

| 0.95 | 0.05-0.20 | 0.05 | 0.10 | 0.15 | 99.0 min | ||||||

| Paramètre welding mahazatra | |||||||||||

| savaivony | DINGANA | Volt | Amps | mandatsa-dranomaso | |||||||

| in | (mm) | ||||||||||

| .030 | (.8) | GMAW | 15-24 | 60-175 | Argon (cfh) | ||||||

| .035 | (.9) | GMAW | 15-27 | 70-185 | Argon (cfh) | ||||||

| 3/64” | (1.2) | GMAW | 20-29 | 125-260 | Argon (cfh) | ||||||

| 1/16” | (1.6) | GMAW | 24-30 | 170-300 | Argon (cfh) | ||||||

| 3/32” | (2.4) | GMAW | 26-31 | 275-400 | Argon (cfh) | ||||||

| savaivony | DINGANA | Volt | Amps | mandatsa-dranomaso | |||||||

| in | (mm) | ||||||||||

| 1/16” | (1.6) | GTAW | 15 | 60-80 | Argon (cfh) | ||||||

| 3/32” | (2.4) | GTAW | 15 | 125-160 | Argon (cfh) | ||||||

| 1/8” | (3.2) | GTAW | 15 | 190-220 | Argon (cfh) | ||||||

| 5/32” | (4.0) | GTAW | 15 | 200-300 | Argon (cfh) | ||||||

| 3/16” | (4.8) | GTAW | 15-20 | 330-380 | Argon (cfh) | ||||||

Wenzhou Tianyu Electronic Co., Ltd. dia naorina tamin'ny taona 2000. Nirotsaka an-tsehatra izahay tamin'ny famokarana electrodes welding, tsora-kazo, ary kojakoja fampiasa nandritra ny 20 taona mahery.

Ny vokatra lehibe indrindra dia ahitana electrodes stainless vy welding, karbaona vy welding electrodes, ambany firaka welding electrodes, surfacing welding electrodes, nikela & kobalta firaka electrodes, malefaka vy & ambany firaka welding tariby, Stainless vy welding tariby, entona voaaro flux cored tariby, tariby aluminium welding, sodina sodina arc.tariby, nikela & kobalta firaka lasantsy tariby, varahina welding tariby, TIG & MIG welding tariby, tungstène electrodes, karbaona gouging electrodes, ary ny hafa welding kojakoja & consumables.