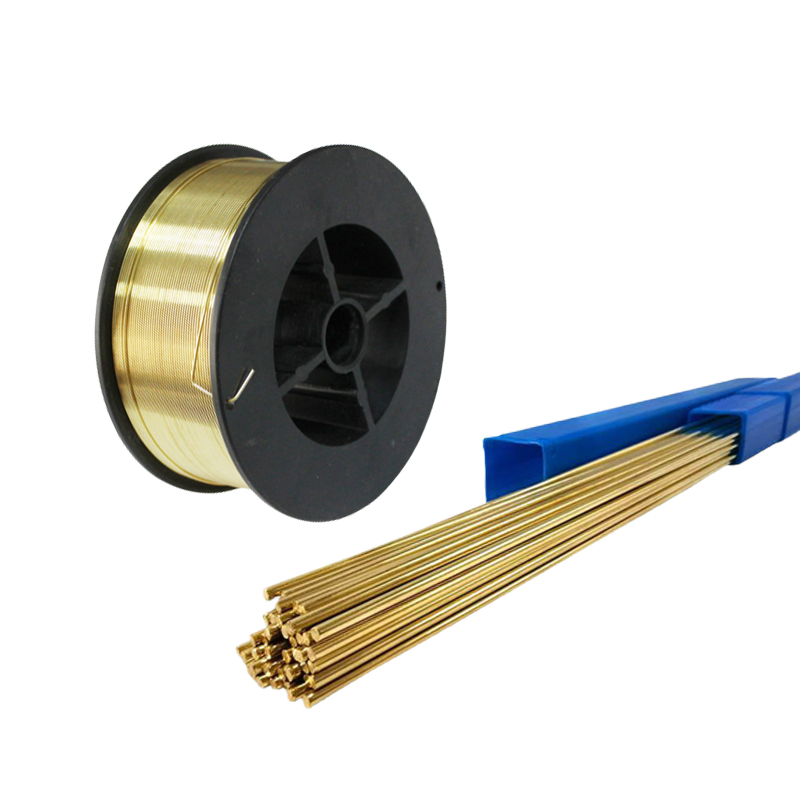

ERCuAl-A1 Aluminum Bronze Welding Wire dia vy tsy misy vy, aliminioma bronze firaka azo alaina amin'ny tariby spooled ary 36" bare-filler tsorakazo ampiasaina amin'ny entona metaly-arc sy entona tungstène-arc welding dingana tsirairay avy.

ERCuAl-A1 Aluminum bronze Welding Wire fametrahana dia ampiasaina voalohany indrindra mba hametahana ny mitondra sy ny tafo-mahatohitra surfaces mitaky hamafin'ny 125 BHN eo ho eo ary mba hanohitra harafesiny indrindra avy amin'ny rano sira, metaly sira, sy ny maro fampiasa matetika asidra amin'ny isan-karazany fifantohana sy ny mari-pana.Ity firaka ity dia tsy soso-kevitra hanatevin-daharana satria ny petra-bola dia tsy manana fironana ho mafana fohy.

ERCuAl-A1 Aluminum Bronze Welding Wire Aluminum Bronze Welding Wire Ny fampiharana dia misy takelaka fantsona, seza valva, fantsom-bozaka, impeller, orinasa simika, ary milina fikosoham-bary.

ERCUAL-A1 ALUMINIUM BRONZE WELDING WIRE FIZIKA SY MEKANIKA:

| Solids-Temperature | 1030 ℃ |

| hakitroky | 7,7 kg/dm³ |

| Elongation | 40-45% |

| Liquids-Temperature | 1040 ℃ |

| Faharetana amin'ny sintona | 380-450N/mm² |

| Brinell Hardness | 100HB |

ERCUAL-A1 ALUMINIUM BRONZE WELDING WIRE PACKING:

| MIG | savaivony | 0.8 – 2.0mm | Fonosana | D100mm D200mm D300mm | lanja | 1kg/5kg/12.5kg/13.6kg/15kg |

| 0.030″-5/64″ | 2lb/10lb/27lb/30lb/33lb | |||||

| TIG | savaivony | 1.6 – 6.4mm | NY FAHARETANY | 457mm / 914mm | Fonosana | 5kg / boaty 25kg / boaty 10kg / fonosana plastika |

| 1/16″ – 1/4″ | 18″ / 36″ | 10lb / boaty 50lb / boaty 10kg / fonosana plastika |

Marihina fa misy vokatra vita amin'ny spool hazo 500lb raha ilaina.

ERCUAL-A1 ALUMINIUM BRONZE WELDING WIRE CHEMICAL COMPOSITE(%):

| Malagasy | ISO24373 | GB/T9460 | GB/T9460 | BS EN14640 | AWS A5.7 | DIN 1733 |

| KILASY | Cu6100 | SCu6100 | SCu6100A | Cu6100 | C61000 | 2.0921 |

| firaka | CuAl7 | CuAl7 | CuAl8 | CuAl8 | ERCuAl-A1 | SG-CuAl8 |

| Cu | bal. | bal. | bal. | bal. | bal. | bal. |

| Al | 6.0-8.5 | 6.0-8.5 | 7.0-9.0 | 6.0-9.5 | 6.0-8.5 | 7.5-9.5 |

| Fe | – | – | max 0.5 | 0.5 | – | max 0.5 |

| Mn | 0.5 | max 0.5 | max 0.5 | 0.5 | 0.5 | max 1.0 |

| Ni | – | – | max 0.5 | 0.8 | – | max 0.8 |

| P | – | – | – | – | – | – |

| Pb | 0.02 | – | max 0.02 | 0.02 | 0.02 | max 0.02 |

| Si | 0.2 | max 0.1 | max 0.2 | 0.2 | 0.1 | max 0.2 |

| Sn | – | – | max 0.1 | – | – | – |

| Zn | 0.2 | max 0.2 | max 0.2 | 0.2 | 0.2 | max 0.2 |

| hafa | 0.4 | max 0.5 | max 0.2 | 0.4 | 0.5 | max 0.4 |